Description

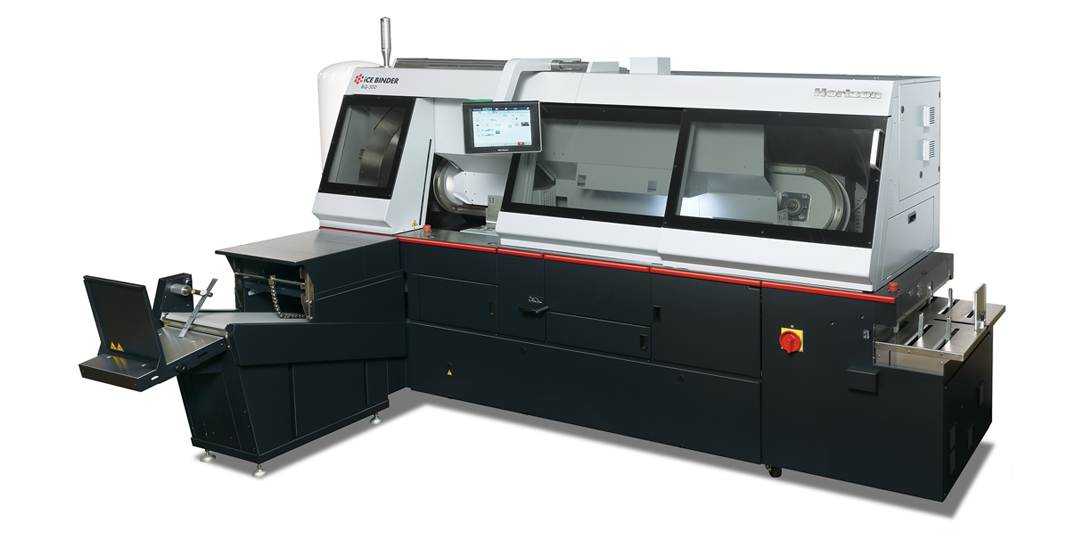

The BQ-500 perfect binder is designed for increased book-of-one productivity, increased automation, and increased quality control over a wider range of substrates regardless of run length. The system features an improved and easy-to-use 12.1” touchscreen for quick setup, an ergonomic design for efficient, operator-friendly operation, and an enhanced delivery system for thin books.

- Variable production: The BQ-500 is the most productive binder for book-of-one production in its class. In a variable range of +/-5mm, the BQ-500 can reach production speeds of up to 800 books per hour, almost double the productivity of other binders in this range.

- Case binding and add-ons: Enhancements like the LBF-500 Book Block Feeder and case binding accessories like the GF-500 Gauze Feeder and ESF-1000 End Sheet Feeder allow you to tailor the BQ-500 to fit your unique production needs.

- For more information on these add-ons, please see the accessories section at the bottom of this page, check out this in-depth video, browse the brochure, and send us a message!

- Advanced automation: The BQ-500 features 21 automated sections in total, reducing setup and changeover time even when making fine variable thickness adjustments – all while ensuring higher quality books.

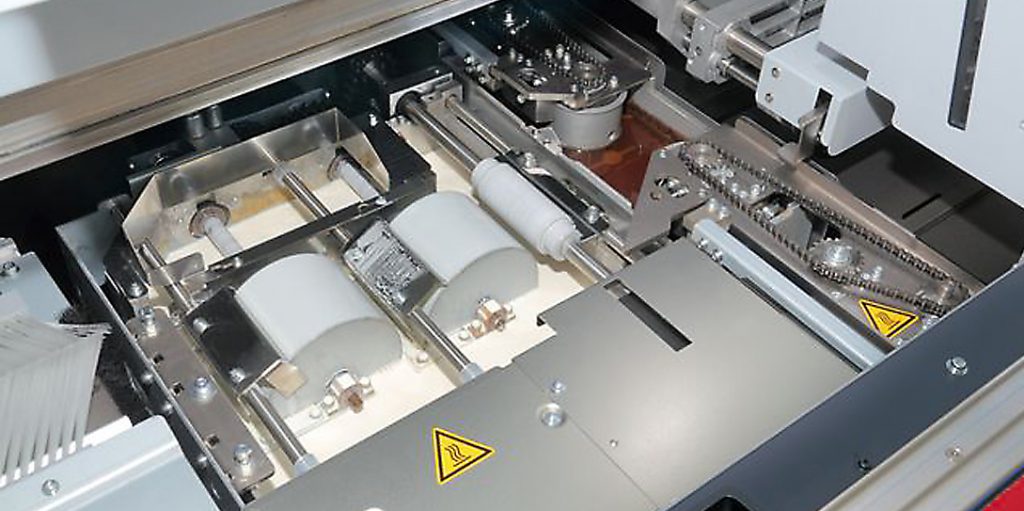

- Clean spine preparation: Improved milling waste removal, a newly designed air flow, and an improved glue application system help ensure high-quality production.

- EVA and PUR: The BQ-500 features interchangeable EVA and PUR glue tanks with a new and improved tank removal process for cleaner and easier tank changeover.

- Gentle delivery: To prevent damage to more delicate books, the BQ-500 has reduced the book drop from 150mm to only 5mm. Books are then gently lowered to the delivery belt.

| Book block | Max: 12.59″ x 12.59″ Min: 5.70″ x 4.13″ |

|

| Cover size | Max: 12.59″ x 26.37″ Min: 5.315″ x 8.859″ |

|

| Cover pile height | 5.90″ | |

| Thickness | Max: 2.55″ Min: 0.039″ |

|

| Cover thickness | Coated: 104 to 348 gsm Uncoated: 81.4 to 302 gsm |

|

| Production Speed | EVA: 1,350 cycles/hr (max) PUR: 1,000 cycles/hr (max) |

|

| Variable Production Speed | Up to 800 books/hr in a variable range of +/- 5mm | |

The LBF-500 can handle various types of book blocks including loose sheets, folded signatures, pre-glued book blocks and sewn book blocks. You can hand drop book blocks at the in-feed conveyor or connect to a wide range of upstream devices capable of producing book blocks for inline production

Gauze width and length can be setup according to book block information from the binder. Gauze application and regular soft cover book production can be switched between from the touchscreen without removing the GF-500 from the binder.

The ESF-1000 adds folded end sheets to the book block. The system can handle various types of book blocks including loose sheet, folded signature, glued book block and sewn book blocks. It can be configured inline or offline.