Description

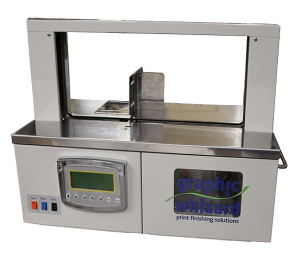

Standard Horizon’s BQ-280PUR Perfect Binder is specially designed to handle the unique requirements of digital print – with digital print friendly processing, quick set-up and changeover for shorter production runs, book-of-one capability, and even in-line verification for document integrity. The BQ-280 also uses environmentally-friendly PUR glue which meets the requirements of Lay-Flat binding for both offset and digital prints as well as coated stock. The large color touchscreen features intuitive icons for easy operation. Simply input book block and cover information at the touchscreen for quick and automatic setup, including carriage clamp, milling, glue tank, nipping, and cover feeder. Up to 200 jobs can be held in memory and “locked” for additional security. The automated, sensor-activated digital caliper system ensures consistent measurement of book block thickness every time, eliminating operator discrepancy. Book thickness is automatically measured by placing the book block into the digital caliper. The caliper slides into position with no manual intervention and thickness data automatically begins set-up. Easily handles the production of digitally printed books, personalized photo books, smaller sample runs, and other ultra short-run work!

- PUR perfect binder: The BQ-280 also uses environmentally-friendly PUR glue which meets the requirements of lay-flat binding for both offset and digital prints as well as coated stock. For more information about PUR binding, click here.

- Easy-to-use touchscreen controls: The large color touchscreen features intuitive icons for easy operation. Simply input book block and cover information at the touchscreen for quick and automatic setup, including carriage clamp, milling, glue tank, nipping, and cover feeder.

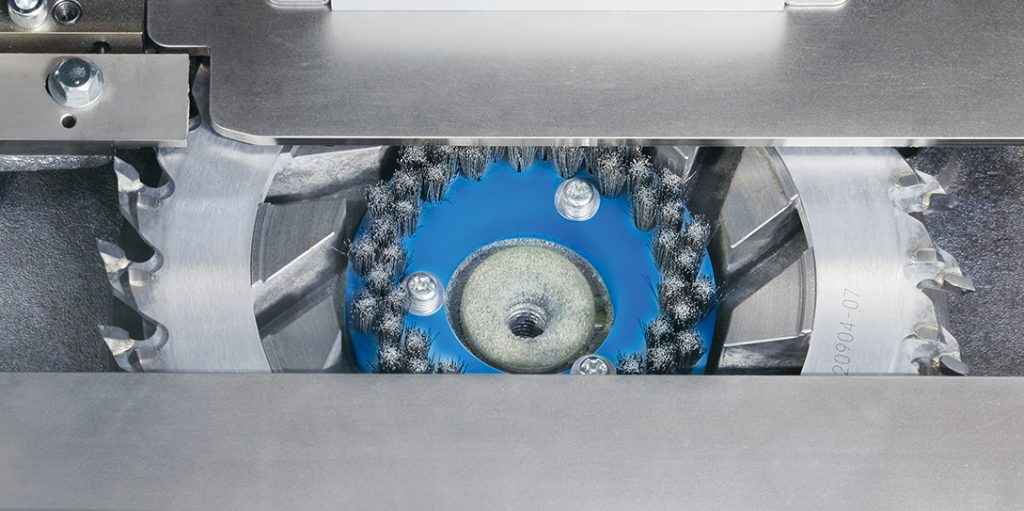

- Precision caliper system: The automated, sensor-activated digital caliper system ensures consistent measurement of book block thickness every time, eliminating operator discrepancy. The caliper slides into position with no manual intervention and thickness data automatically begins set-up.

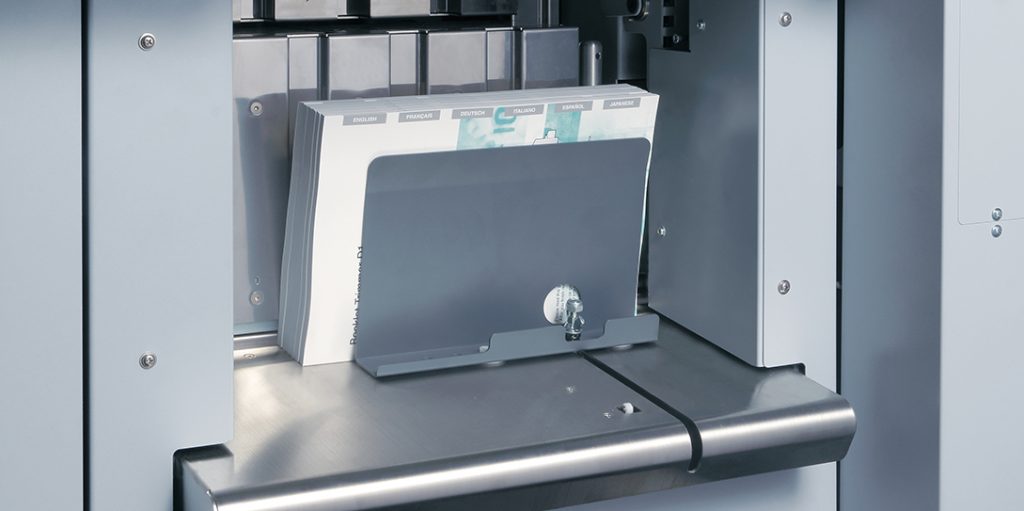

- Store jobs for quick setup: Up to 200 jobs can be held in memory and locked for additional security.

- Designed for print-on-demand: Easily handles the production of digitally printed books, personalized photo books, smaller sample runs, and other ultra short-run work!